Industrial operations rely on efficient and reliable equipment to maintain productivity, and one such critical component is the rotary gear pump. Known for their precision, durability, and versatility, rotary gear pumps play a vital role in handling a wide variety of fluids across industries. This blog post will serve as a guide to understanding how rotary gear pumps work, their applications, and why they are indispensable in industrial settings.

Industrial operations rely on efficient and reliable equipment to maintain productivity, and one such critical component is the rotary gear pump. Known for their precision, durability, and versatility, rotary gear pumps play a vital role in handling a wide variety of fluids across industries. This blog post will serve as a guide to understanding how rotary gear pumps work, their applications, and why they are indispensable in industrial settings.

What Are Rotary Gear Pumps?

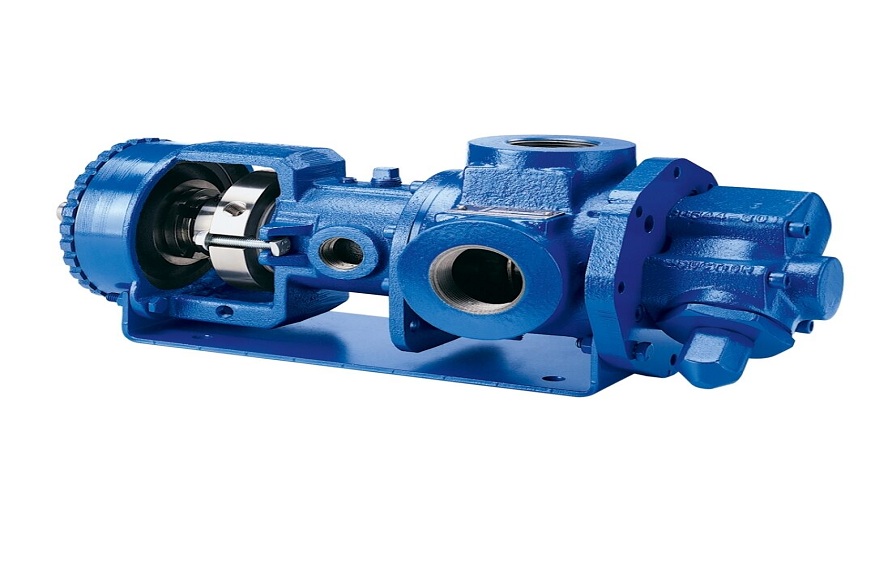

A rotary gear pump, often referred to as a gear pump, is a type of positive displacement pump designed to transfer fluids by relying on the rotational motion of gears. Unlike centrifugal pumps that use high-speed impellers to move fluid, rotary gear pumps displace a fixed amount of fluid with each turn of the gears, making them highly efficient for precise applications.

Gear pumps are known for their ability to handle high-viscosity fluids, making them suitable for applications involving oils, adhesives, resins, and even molasses. Their robust construction and precise operation have positioned them as a reliable choice for industries such as chemicals, food processing, and manufacturing.

Key Components of Rotary Gear Pumps

A rotary gear pump is composed of the following main components:

- Gears: Two or more gears are central to the pump’s operation. These can be external (two gears rotating in opposite directions) or internal (one gear fits within another for rotation).

- Housing: A tightly sealed chamber encases the gears to prevent leakage and maintain pressure.

- Drive Mechanism: The motor or engine that powers the rotation of the gears.

- Seals and Bearings: These components ensure the pump operates smoothly and prevent contamination.

Understanding these elements is key to appreciating how rotary gear pumps function effectively in diverse applications.

How Do Rotary Gear Pumps Work?

The operating principle of rotary gear pumps is relatively straightforward but incredibly effective. Here’s how it works:

- Fluid Intake: When the pump is in operation, the drive gear starts to rotate, engaging the second gear (also known as the idler gear). This creates a suction effect on the intake side of the pump, drawing the fluid into the chamber.

- Fluid Transfer: The rotation of the gears traps the fluid in the cavities between the gear teeth and the pump housing. The fluid is then carried along the periphery of the gears.

- Fluid Discharge: As the gears continue to rotate, the trapped fluid is pushed toward the discharge side of the pump. The meshing of the gear teeth on the outlet side creates a seal, forcing the fluid out of the pump at a steady and controlled rate.

The positive displacement nature of the pump ensures consistent fluid flow, regardless of fluctuations in pressure, making rotary gear pumps ideal for precision-driven tasks.

Types of Rotary Gear Pumps

There are two primary types of rotary gear pumps:

- External Gear Pumps: These feature two identical gears that rotate against each other. They are typically used for high-pressure applications and can manage a wide range of fluid viscosities.

- Internal Gear Pumps: These involve a smaller internal gear rotating within a larger, crescent-shaped external gear. Known for their quieter operation and ability to handle thick, viscous fluids, internal gear pumps are common in industries like food processing and petrochemicals.

Applications of Rotary Gear Pumps

Rotary gear pumps are versatile and find applications in numerous industries thanks to their ability to handle a wide range of fluids, including those with high viscosity or abrasive properties. Below are some key applications:

Chemical Industry

Rotary gear pumps are extensively used in the chemical industry for transferring aggressive or corrosive liquids like acids and solvents. Their precise functionality ensures the safe and efficient handling of these hazardous materials.

Oil and Gas

From lubricating oil systems to refined product transfer, rotary gear pumps are a staple in the oil and gas sector. Their ability to operate under high pressure makes them ideal for transferring fuel oils and other petrochemical products.

Food and Beverage

Food-grade rotary gear pumps handle items like syrups, chocolate, and other viscous, edible materials. Their hygienic designs ensure compliance with food safety standards.

Manufacturing

The manufacturing industry relies on rotary gear pumps for applications such as hydraulic fluid transfer, lubrication systems, and adhesive dispensing.

Pharmaceuticals

Rotary gear pumps are frequently used in the pharmaceutical sector to transfer viscous materials and delicate liquids with precision, ensuring consistency in production.

Benefits of Using Rotary Gear Pumps

The popularity of rotary gear pumps stems from various advantages that make them essential in industrial applications:

- Precision: These pumps deliver accurate and consistent flow rates, making them ideal for processes where precision is critical.

- Versatility: They can handle a wide range of fluids, including those with varying viscosities and abrasive characteristics.

- Compact Design: Their relatively small size enables easy installation in tight spaces without compromising performance.

- Durability: Built with robust materials, rotary gear pumps can withstand demanding industrial conditions, extending their lifespan.

- Efficiency: With minimal energy loss and steady performance under varying pressures, rotary gear pumps offer operational efficiency.

Maintaining Your Rotary Gear Pump for Longevity

Proper maintenance extends the life of your rotary gear pump, ensuring seamless operation. Here are a few recommendations:

- Regular Inspections: Conduct routine checks for wear and tear, especially on the seals, gears, and bearings.

- Lubrication: Ensure that the pump is adequately lubricated to reduce friction and prevent premature wear.

- Cleaning: Clean the pump thoroughly to avoid material build-up, especially when handling viscous or abrasive fluids.

- Prompt Repairs: Address any leaks or performance issues immediately to prevent further damage.

By following these practices, you can ensure that your rotary gear pump operates at peak efficiency.

Optimize Your Fluid Handling with Rotary Gear Pumps

Rotary gear pumps are indispensable in modern industries, offering a reliable, efficient, and precise solution for fluid handling. Whether you’re in food production, oil and gas, or manufacturing, these pumps provide the performance and durability needed to keep operations running smoothly.

If you’re considering incorporating rotary gear pumps into your operations, ensure you choose a trusted manufacturer with expertise in industrial applications. The right gear pump can elevate your processes, reduce downtime, and enhance your operational efficiency.

Leave a Reply

You must be logged in to post a comment.