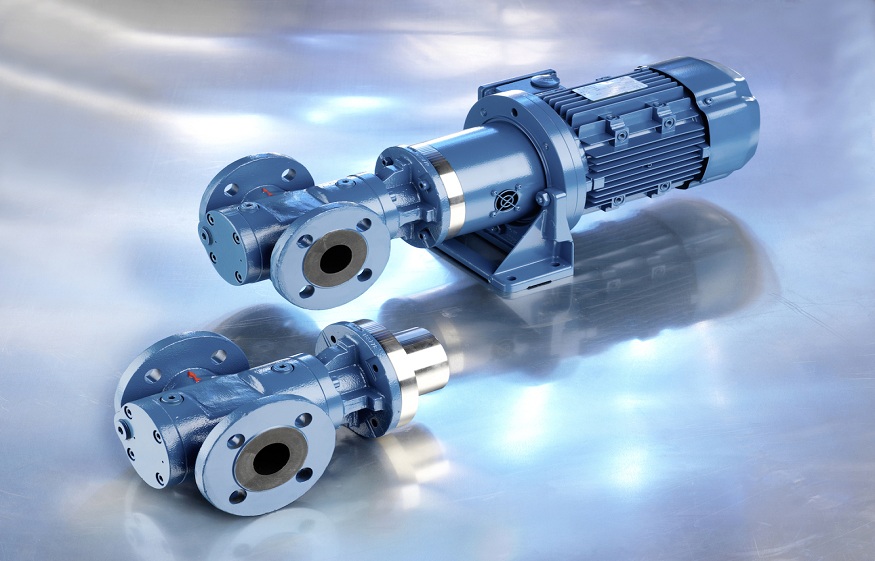

Lube oil pumps are critical components in industrial machinery, ensuring consistent lubrication of engines, turbines, and hydraulic systems. Without proper maintenance, these pumps can wear out prematurely, leading to costly repairs, unscheduled downtime, and reduced equipment efficiency. Understanding the best maintenance practices is essential for operators, engineers, and plant managers who want to extend the life of lube oil pumps and maintain optimal system performance.

In this article, we explore practical maintenance strategies, key considerations, and expert recommendations to maximize the reliability of lube oil pumps. We also highlight the importance of working with reputable oil pump manufacturers to ensure long-term performance.

Understanding Lube Oil Pumps

Lube oil pumps are designed to circulate lubricant through machinery, reducing friction, dissipating heat, and preventing wear on moving parts. They can be found in a variety of systems, from large industrial engines to precision hydraulic equipment.

The performance of a lube oil pump depends on its design, the quality of lubrication, and the operational environment. While the pump may appear to operate smoothly under normal conditions, factors such as oil contamination, improper installation, and inconsistent maintenance can significantly shorten its lifespan.

Regular Inspection and Monitoring

Routine inspection is the cornerstone of effective lube oil pump maintenance. Regular checks allow early detection of potential issues, preventing minor problems from escalating into major failures. Key areas to monitor include:

- Pump Noise and Vibration: Unusual sounds or excessive vibration can indicate misalignment, cavitation, or worn internal components.

- Flow Rate and Pressure: Monitoring flow and pressure ensures the pump is delivering the correct volume of lubricant to the system. Deviations may indicate internal wear or blockage.

- Oil Condition: Checking for contamination, viscosity changes, or the presence of water or particles helps maintain proper lubrication and reduces wear on pump components.

Implementing a routine inspection schedule and maintaining detailed records enables operators to detect trends and predict maintenance needs before failures occur.

Ensuring Proper Installation

Proper installation is critical to the longevity of lube oil pumps. Even minor errors can lead to inefficiency and premature wear. Best practices include:

- Alignment: Ensuring the pump and driver shaft are correctly aligned minimizes mechanical stress and reduces vibration.

- Mounting: Secure and level mounting prevents structural strain and helps maintain consistent pump operation.

- Connections: Properly fitted inlet and outlet connections prevent leaks, cavitation, and pressure fluctuations.

Consulting installation guidelines provided by oil pump manufacturers ensures that pumps are installed to operate at peak efficiency and reduces the risk of early failures.

Lubricant Selection and Management

The type and quality of lubricant used significantly impact the performance and lifespan of lube oil pumps. Using the correct viscosity and adhering to manufacturer recommendations is crucial. Key considerations include:

- Oil Quality: High-quality oil reduces wear and prevents the buildup of deposits inside the pump.

- Contamination Control: Using filters and maintaining clean oil reduces damage caused by particles or debris.

- Temperature Management: Maintaining proper oil temperature ensures consistent viscosity and prevents thermal degradation of the pump components.

Regular oil analysis helps identify contamination or chemical changes early, allowing corrective action to protect the pump and the machinery it serves.

Scheduled Preventive Maintenance

Preventive maintenance is essential for keeping lube oil pumps in optimal condition. Unlike reactive maintenance, which addresses issues after they occur, preventive maintenance focuses on routine care to prevent failures. Best practices include:

- Component Inspection: Regularly check gears, seals, bearings, and shafts for wear and tear.

- Seal Replacement: Worn or damaged seals can cause leaks and reduce pump efficiency. Replacing them at scheduled intervals prevents unexpected failures.

- Bearing Maintenance: Bearings should be lubricated and inspected for signs of wear or overheating. Proper bearing care ensures smooth operation.

- Filter Changes: Regularly replace or clean filters to maintain oil cleanliness and prevent pump damage.

Following a preventive maintenance schedule recommended by oil pump manufacturers enhances reliability and reduces costly downtime.

Avoiding Common Operational Mistakes

Many lube oil pump failures are caused by operational mistakes rather than mechanical defects. Avoiding these common errors can significantly extend pump life:

- Running Dry: Operating a pump without sufficient lubricant can cause immediate damage to internal components. Always ensure the pump is properly primed.

- Overheating: Excessive temperature can degrade oil and damage pump materials. Monitor temperature and install cooling systems if needed.

- Overpressure Conditions: High pressure can strain the pump and connected components. Pressure relief valves and monitoring systems help prevent damage.

- Incorrect Speed: Operating outside the recommended speed range can cause cavitation, vibration, and uneven wear. Follow manufacturer guidelines carefully.

Training operators and maintenance personnel on correct procedures ensures that lube oil pumps are handled safely and efficiently.

Cleaning and Contamination Control

Keeping the pump and surrounding system clean is vital for long-term reliability. Contaminants such as dirt, metal particles, or moisture can accelerate wear and reduce efficiency. Best practices include:

- System Flushing: Periodically flush the pump and lines to remove accumulated debris.

- Filter Maintenance: Ensure filters are correctly installed and replaced according to schedule.

- Environment Control: Maintain a clean operating environment to minimize contamination risk.

Proactive contamination control reduces maintenance costs, extends pump life, and improves overall system performance.

Working with Reputable Oil Pump Manufacturers

Choosing lube oil pumps from trusted oil pump manufacturers ensures access to high-quality components, technical support, and maintenance guidance. Reputable manufacturers provide detailed documentation, recommended maintenance schedules, and troubleshooting advice that can prevent costly errors and extend the life of the pump.

Additionally, working with experienced manufacturers allows for customization of pump design to suit specific operational requirements. This ensures optimal performance in demanding industrial applications and provides peace of mind regarding reliability and safety.

Advanced Monitoring and Predictive Maintenance

Modern industrial facilities increasingly rely on monitoring technology and predictive maintenance strategies to extend equipment life. Sensors and real-time monitoring systems can track pump performance, oil condition, and operational parameters. Predictive maintenance uses this data to forecast potential failures and schedule maintenance before problems arise.

For lube oil pumps, predictive strategies may include:

- Vibration Analysis: Detecting early signs of imbalance or wear in bearings and gears.

- Oil Analysis: Monitoring viscosity, contaminants, and chemical composition.

- Temperature Tracking: Identifying overheating trends before they cause damage.

Implementing predictive maintenance improves reliability, reduces unexpected downtime, and optimizes the life cycle of lube oil pumps.

Lube oil pumps are critical to the safe and efficient operation of industrial machinery. Extending their life requires a combination of proper installation, regular inspection, preventive maintenance, and careful operational practices. Choosing the right lubricant, controlling contamination, and avoiding common operational mistakes are essential to maintaining pump reliability.

Working closely with trusted oil pump manufacturers ensures access to high-quality equipment, technical guidance, and maintenance recommendations that support long-term performance. By following these best practices, operators can reduce downtime, improve efficiency, and maximize the lifespan of their lube oil pumps, ensuring smooth and reliable operation in demanding industrial environments.

Leave a Reply

You must be logged in to post a comment.